EU-MORE final event summary report

Boosting energy savings in industry and the service sector by accelerating replacement of old and inefficient electric motors.

The final event of the EU-MORE project took place in Brussels on March 11th. About 50 participants attended the event, where they had the opportunity to learn about the achievements of the EU-MORE project and provide valuable feedback on the policy recommendations and tools developed.

Beside speakers from our EU-MORE projects, we were proud to welcome also presentations from the other LIFE x3 Cluster projects: AUDIT2MEASURE and KNOWnNEBs, as well as DG Ener and CLASP.

The presentation PPT slide decks can be downloaded here: final event presentations

Please download the summary report here:

Date & Time

March 4, 2025 ; 15h00 - 16h00 CET

Speaker

Kurt Stockman, Ghent University, Department of Electromechanical Systems and Metal Engineering

recording on YouTube here: https://youtu.be/WBQ0K9pCvLU

Description

This webinar outlines the process of implementing a successful worldwide motor replacement programme at a large steel wire company. To meet its sustainability goals, the company decided to evaluate the potential benefits of upgrading to high-efficiency motors (IE4 or IE5) in its wire drawing machinery. The installed base consists of over 1,000 machines, which originally used frequency-controlled IE2 and IE3 induction motors.

Prof. Kurt Stockman of Ghent University will discuss the various phases of the project, starting with the collection of energy efficiency data from manufacturers. He will also cover the validation testing of this data based on motor performance assessments and an analysis of the compatibility of the selected high-efficiency motors with the original power electronic converters. The motor analysis includes induction motors, synchronous reluctance motors, and permanent magnet motors.

Following the technical evaluation of potential energy savings, the economic factors, including payback periods, were analysed. Additionally, the presentation will address the complexities of different energy costs across various regions worldwide and their impact on the payback period.

Finally, the speaker will discuss the actual rollout of the motor replacement initiative and share the initial field results of the energy measurements.

Following the presentation, you will have plenty of time to engage with the speaker during the Q&A session.

Maximizing energy efficiency in industry: Insights and policy recommendations from three EU-LIFE projects

Date & Time

February 21, 2025 ; 10h00 - 11h30 CET

Speakers

Recording on YouTube: https://youtu.be/aEHegIaE7MU

Description

EU-MORE, AUDIT2MEASURE, and KNOWNnNEBs—three LIFE co-funded projects aimed at promoting energy efficiency in industry—share their insights and policy recommendation for accelerating the implementation of energy efficiency measures.

AUDIT2MEASURE: Boost the impact of audits: How to implement Art. 11 of the EED into national legislation

Under the new Energy Efficiency Directive (EED), EU Member States are required to transpose the provisions of the new Article 11 of the revised EED (formerly Article 8) into national law by October 2025. The first version of AUDIT2MEASURE’s policy recommendation report provides insights and guidance on how national policymakers can improve the impact of their current national energy audit systems, fill current gaps, go beyond the minimum European requirements and how the European Commission could further support efforts to reduce energy consumption and greenhouse gas emissions in the industry.

download presentation here: https://eu-more.eu/wp-content/uploads/2025/03/01-AUDIT2MEASURE.pdf

KNOWnNEBs: Beyond Energy Savings: A comprehensive decision-making tool for Energy Efficiency in industry

This presentation introduces a comprehensive tool created under the KNOWnNEBs project for assessing energy efficiency measures. The tool captures energy savings and considers intangible benefits, such as improved air quality, increased productivity, and enhanced product quality. It also recognizes potential drawbacks, including operational disruptions, staff training complexities, and the risk of low construction quality. By utilizing advanced financial metrics like NPV, IRR, and ROI, along with a novel benefit indicator, it helps industry professionals, policymakers, and other stakeholders make informed decisions on energy efficiency investments. This ultimately leads to more effective industry practices and policy outcomes.

download presentation here: https://eu-more.eu/wp-content/uploads/2025/03/02-KNOWnNEBs.pdf

EU-MORE: Policy Review and recommendations for accelerating the replacement of old and inefficient motors

Electric motors used in industrial applications often remain in service beyond their expected lifespan, limiting the benefits of newer, more efficient motors. The EU-MORE project aims to capitalize on the advantages of accelerating the replacement rate of old, inefficient motors by developing new policies. To achieve this, a review of past and current policies affecting industrial electric motors in the 27 EU Member States was conducted. The presentation comprises the results of the EU-MORE Policy Review and the developed sets of Policy Recommendations taking into account feedback – among other - from discussions with stakeholders during national and co-creation workshops.

download presentation here: https://eu-more.eu/wp-content/uploads/2025/03/03-EU-MORE.pdf

recordings of our webinar now available here

Speaker

Robin Barkhausen, Fraunhofer ISI

Description

This webinar will discuss the EU-MORE Motor Model, designed to evaluate impacts from electric motor replacement policies. By allowing users to input various data, the model assesses the impacts on energy demand, material consumption and greenhouse gas emissions related to different policies. Its comprehensive stock model integrates these inputs to project outcomes such as energy and CO2 savings effectively. The results provide users, particularly policy makers, with a valuable tool for evaluating the implications of their policies.

Key takeaways

- The model clearly explains the impact of electric motor policy on energy, economic, and climate outcomes from the perspectives of policy makers and end users.

- Stakeholders can tailor the model to assess the policy impacts of replacement schemes, enhancing its practical relevance.

- The approach supports informed decision-making by policymakers on improvements to motor systems.

What are key success factors of financial incentive programmes for efficient electric motor systems?

Recording of our webinar now available here:

Speaker

Description

This webinar dives into the key insights from a recent Swiss study on the success factors of financial incentive programmes for electric motor systems.

Rita Werle, CEO and owner of Impact Energy, will discuss:

-

Evaluation of Swiss competitive tenders: A deep dive into competitive tenders as a tool for subsidising energy efficiency improvements in electric motor systems and other energy-consuming equipment.

- Building blocks of financial incentive programmes: Key factors for success in creating effective financial incentives for motor systems, with a focus on design and implementation.

- Exploring possible financial incentive modalities: Discussion on different approaches, including the balance between standard measures and tailored incentives, and their impact from a programme management and energy-saving perspective.

- Insights into Swiss energy efficiency obligations: An overview of ongoing efforts in Switzerland to implement an energy efficiency obligation scheme for utilities.

Key takeaways

- Key factors of a successful programme:

- Contact to programme participants

- Awareness within target group

- Easy participation

- Tangible subsidy

- Qualification of involved consultants

- Programme design depends on the objectives

- Switzerland goes ahead with energy efficiency obligations for electricity suppliers

Boosting efficiency: EU-MORE’s policy review on replacing inefficient motors in industry and services

Recordings of our webinar now available here:

Speakers

- Ronald Piers de Raveschoot, European Commission DG ENER.B3

- Ivan Sangiorgio, IEECP

- João Fong, ISR University of Coimbra

Description

Electric motors used in industrial applications often remain in service beyond their expected lifespan, limiting the benefits of newer, more efficient motors. The EU-MORE project aims to capitalize on the advantages of accelerating the replacement rate of old, inefficient motors by developing new policies. To achieve this, a review of past and current policies affecting industrial electric motors in the 27 EU Member States was conducted. The review includes 64 policy measures aimed at promoting the early replacement of motors to improve energy efficiency in industries. Each policy measure was characterized with details such as the national responsible authority, implementation timeline, available budget, and impacts on electricity savings and replaced industrial motors.

The review process relied on contributions from various country experts who provided a high-level perspective on the national policies under examination. The results show a strong prevalence of financial measures (subsidies and loans), followed by mandatory standards, fiscal measures, and voluntary agreements. The review also highlighted a significant lack of measures targeting trainings and information, deemed particularly relevant for industrial SMEs. Few national policies are incorporating systemic approaches to motor systems, such as including the supply and demand sides of motive power.

The review is complemented by an analysis of relevant motor policies implemented outside the European Union.

Key takeaways

- The EU-MORE project has conducted a review of EU policies supporting the early replacement of electric motors, highlighting the predominance of policies addressing only economic barriers.

- Only a few programs in the EU have tried to tackle information and behavioral barriers.

- The replacement of inefficient motors is generally integrated into cross-cutting programs that do not define specific eligibility criteria for motor replacement.

- The effectiveness of policy measures supporting motor replacement actions is difficult to assess due to the general lack of publicly available data about the policy impact.

- 2 Ronald Piers

- 3 Ivan Sangiorgio

EU-MORE at Coiltech Germany in Mar 2024

Trends in motor technologies, and why old electric motors should be replaced faster – presented by the EU-MORE project at Coiltech trade show & World Magnetic Conference in Augsburg end of March 2024.

Early 2024, EU-MORE has reached its next milestone with the publication of a comparative review on motor technologies, including an analysis of motor system optimization benefits. MEPSs for motors have led to major improvements in the energy efficiency of motors, which now reach levels known as Super- and Ultra-Premium Efficiency Motors (IE4 and IE5). This review discusses the latest trends in IM, SynRM and PM, highlights some aspects of direct-on-line starting motors. The review also digs into the energy saving potential of VSDs, further digitalization and other types of system optimization.

Speeding up the adoption of state-of-the-art electric motors

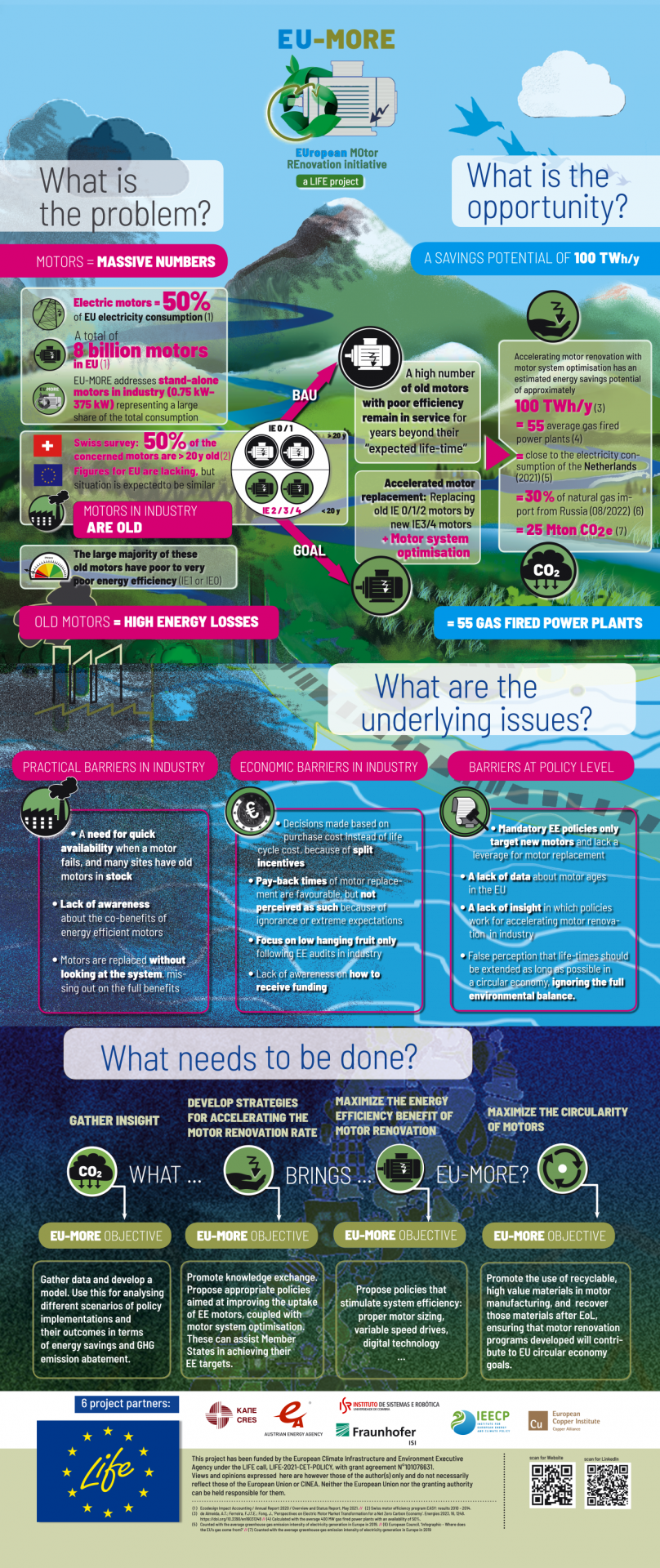

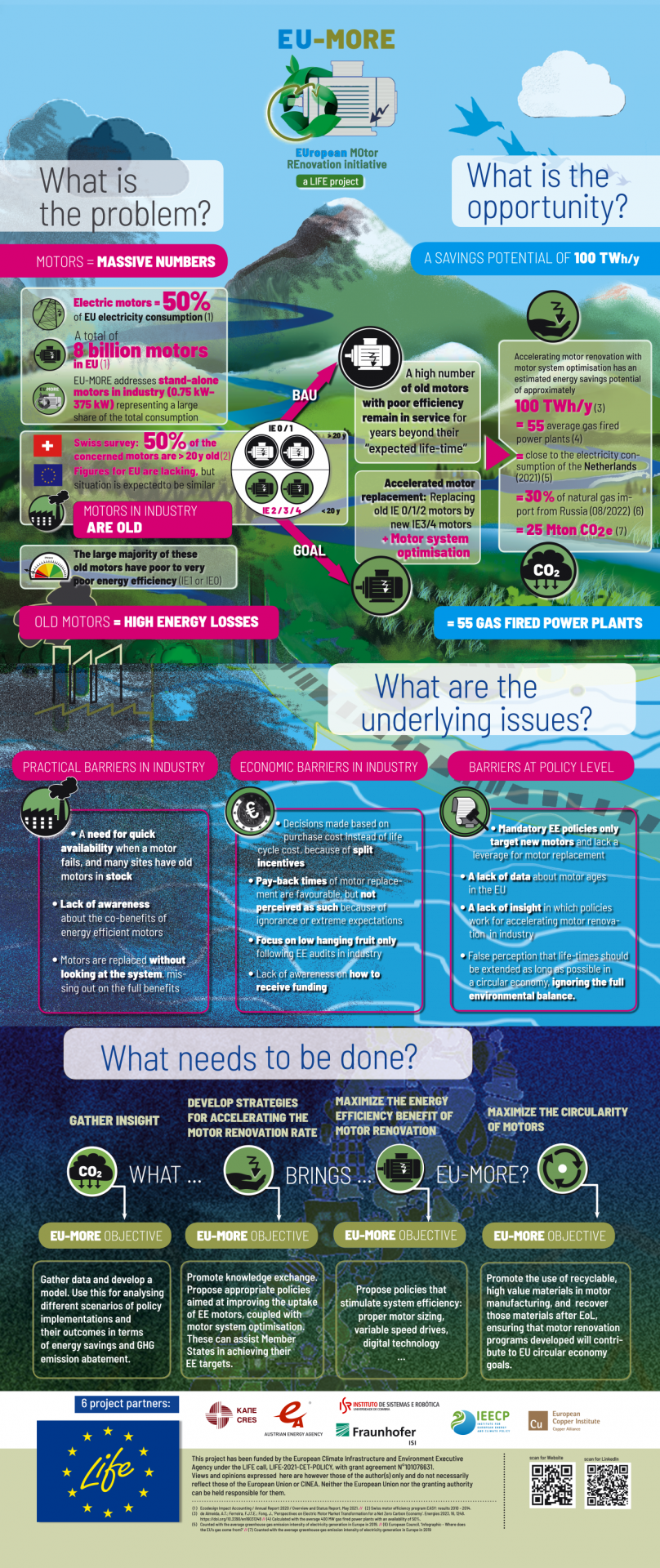

The European project EU-MORE (an acronym for EUropean MOtor REnovation initiative) aims at seizing the benefits deriving from the acceleration of the replacement rate of old inefficient motors through the development of new policies.

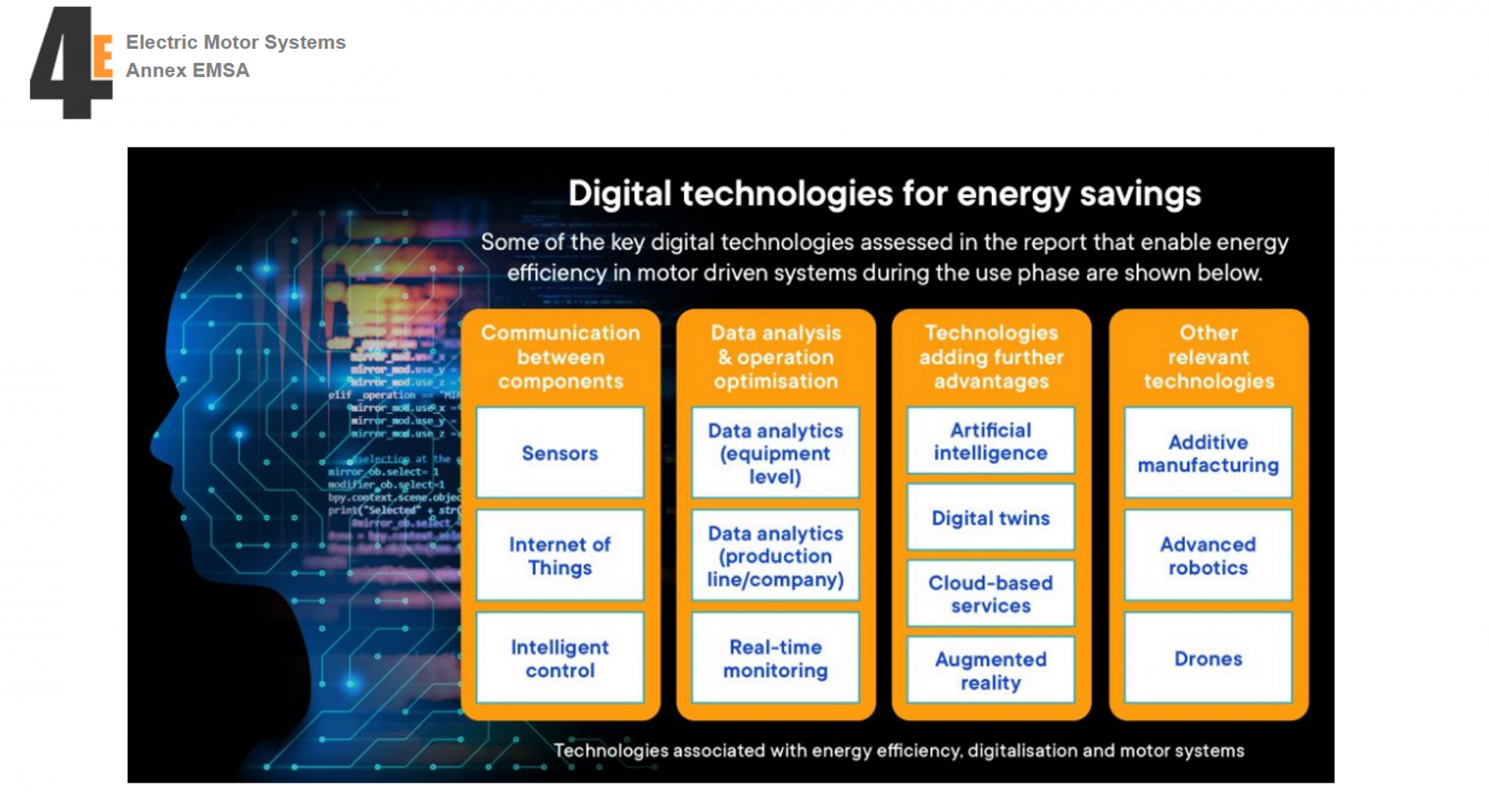

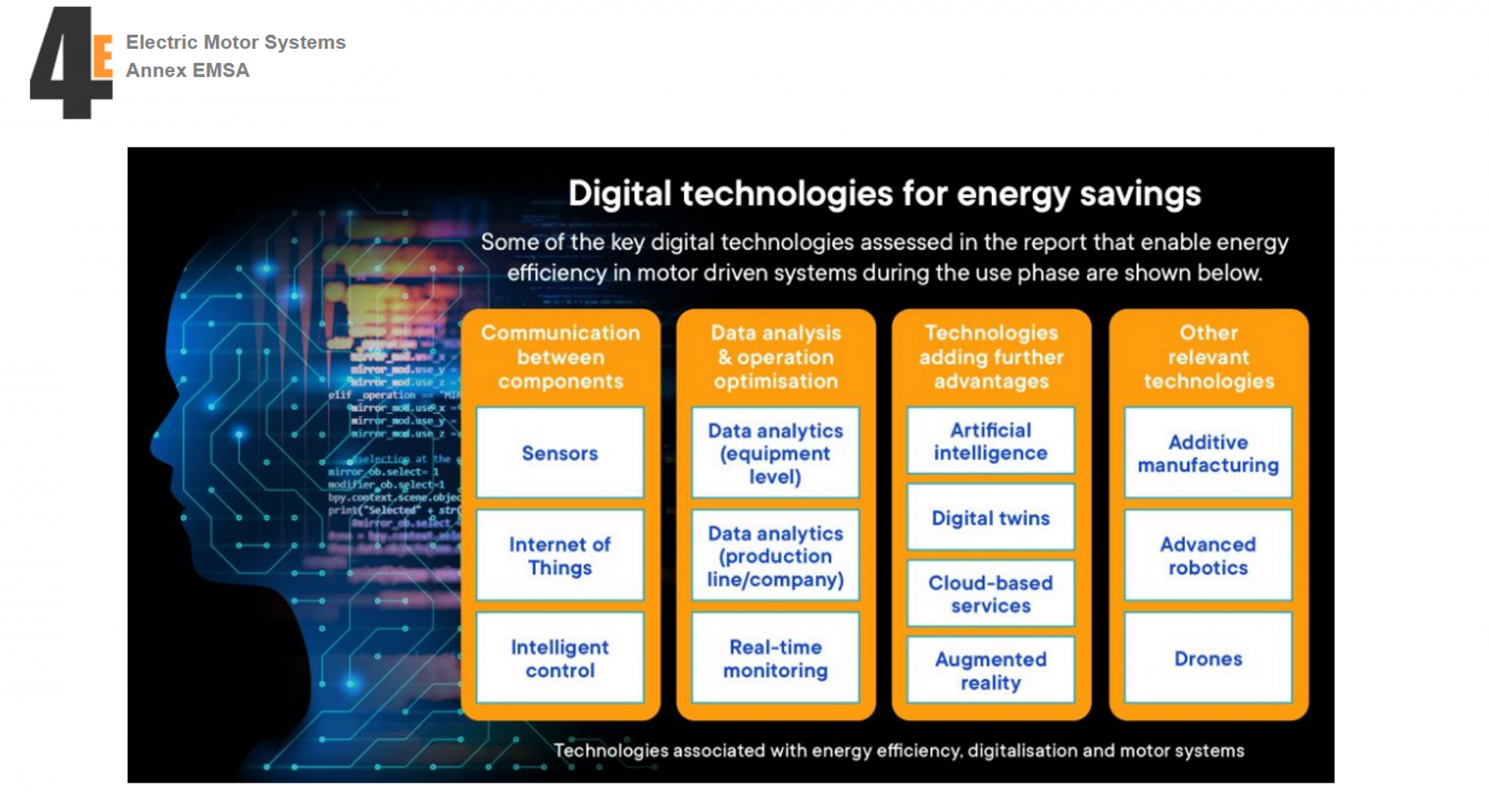

EMSA policy brief: Key findings on digitalisation technologies for motor systems

This Policy Brief gives an overview of the content of the EMSA report on

Classification of digitalisation technologies for electric motor driven systems.

The report identifies 13 digital technologies with the potential to influence energy

consumption in electric motor driven systems and contains definitions, descriptions and examples in this area.

Perspectives on Electric Motor Market Transformation for a Net Zero Carbon Economy

New paper by

Anibal T. de Almeida , Fernando J. T. E. Ferreira and João Fong

Department of Electrical and Computer Engineering, ISR-University of Coimbra, Portugal

As electric motors systems represent such a large share of the overall electricity consumption (over 50%), large savings potential could be made available by the use of energy-efficient motor systems both in new installations and by accelerating the replacement of old inefficient motors. Since electric motors are very reliable, their lifetime is long (according to recent studies it may exceed 20 years) which translates into a very inefficient existing stock despite worldwide policy efforts. This paper analyzes the current efficiency of the installed stock and the causes for its low efficiency, possible policy options to increase its the efficiency, the role of new technologies and improvements possible by targeting the entire motor system at the time of motor replacement. The paper presents an innovative analysis of the estimated impact of increasing the uptake of high-efficiency motors and motor systems; effective policies could translate into 100 TWh/year in the European Union if additional measures, such as addressing oversizing, proper controls (VSDs) and digitisation, are also implemented

ENERGY-EFFICIENT ELECTRIC MOTORS AND MOTOR SYSTEM

Improving energy efficiency is the fastest, cheapest and cleanest way to get reliable power to more people. Well over half of the world's electricity is consumed

by just four products: electric motor systems, lighting, room air conditioners, and residential refrigerators.

ENERGY EFFICIENT INDUSTRIAL MOTORS

Electric motors are of utmost importance in industrial as well as agriculture sector. These motors found their application as constant speed drives with very low rating as well as variable speed drives with very high rating. This paper describes the various factors affecting the efficiency of motor and method to increase it on the basis of comparison with various standards. An incremental difference in the efficiency is also discussed.

Deliverable D4.4 – Report on non-energy benefits in electric motors

The EU-MORE project, under Deliverable D4.4, explores the significant non-energy benefits (NEBs) of replacing old, inefficient motors by high-efficiency electric motors and motor systems across industries. Beyond the conventional focus on energy savings, this report highlights the broader advantages of high-efficiency motor technologies, such as improved operational reliability, productivity, environmental sustainability, and workforce conditions.

High-efficiency motors and motor systems offer a transformative solution to industrial challenges, driving energy efficiency, cost savings, productivity and sustainability. By leveraging technological innovations and robust policies, industries can unlock the full potential of both energy and non-energy benefits, contributing significantly to climate goals and economic competitiveness.

Overview document for D4.5 Stock model policy support documents

Deliverable D4.5 of the EU-MORE project has three major components:

1) Interactive Presentation: This part is designed to provide a comprehensive understanding of the model, which was developed earlier. It will guide the user through the functionalities and applications of the model.The primary aim is to enhance the ease of access and utilization of the policy impact assessment tool, facilitating improved national reporting for energy and climate plans. The presentation is divided into four main sections:

- Genesis: This section delves into the motivation and requirements that led to the development of the model. It provides a clear understanding of the evolution and functionality of the model.

- Exploration: This part serves as a guide on how to get started with the tool and outlines the process of calculating policy impacts.

- Application: This segment presents both theoretical and practical examples of country-specific case studies, showing how the model can be applied in real-world scenarios.

- Reflection: This section discusses the prerequisites and limitations of the model and provides an outlook on potential future developments and applications.

Please download the Interactive Presentation here:

D4.5_EU-MORE_InteractiveSlidedoc.pdf

2) Tutorial Videos: These are instructional materials that provide step-by-step guidance on how to use and apply the stock model. It will support users in understanding the practical application of the model. You can watch the Tutorial Videos on YouTube here:

3) Policy Briefs: These documents will give an overview of motor-related policies, their impact, and how the model can be used to analyze these policies. They are primarily aimed at transferring knowledge about policies, with references to the model for contextual understanding.

The Policy Briefs serve as an extension of the Interactive Presentation and Tutorial Video. They provide in-depth insights into five specific areas, each covered in a standalone document. Each of these five Policy Briefs are here provided in different languages to download at following links:

1) Subsidy scheme

2) Tax Incentive in combination with Voluntary Agreement

3) Information Campaign and Capacity Building

4) Non-Energy Benefits

5) Integrated Approach

The first three briefs are based on policies from policy impact analysis and also provide a few hints on their implementation in the model. The fourth brief on non-energy benefits offers suggestions on how to bolster the practical relevance of such benefits in motor systems. The fifth brief explores the interplay between policies and looks at policy mix, demonstrating that no policy stands alone and that the best approach is often a combination of policies.

All these components aim to enhance the understanding of the model and its application in policy analysis and impact assessment, thereby empowering stakeholders, particularly policy makers.

Deliverable D2.3 – Co-Created Policy Recommendations for Electric Motor Renovation

The Deliverable D2.3 - Co-Created Policy Recommendations for Electric Motor Renovation outlines general and national policy recommendations to accelerate the replacement of inefficient electric motors across Europe.

This document builds on previous assessments as described in Deliverable D2.2 – Motor Policy Review and incorporates insights gathered from the National Workshops and Co-Creation Workshops organised by the project, along with other significant project results.

The report firstly examines the several barriers slowing down the replacement of old and inefficient electric motors, including high upfront costs, lack of awareness among businesses, behavioural barriers and gaps in regulations that make them fail to encourage the transition to efficient motors.

An analysis of policy instruments that could help overcome these obstacles is then provided. Each instrument is analysed according to its success factors, barriers to implementation, and cost-effectiveness – assessments which are based on past programs and evaluations.

Building on these insights, the report proposes a set of general policy recommendations. A comprehensive approach that combines financial incentives, regulatory requirements, and information campaigns would be the most effective strategy. Although such an integrated approach would be more resource intensive and time-consuming than individual policy measures, it would result in the highest return on the public investment.

A “stick-and-carrot” approach, which offers incentives for some motor efficiency improvements while enforcing mandatory upgrades for the most outdated systems, could create the intended shift while keeping industry engagement high. The importance of long-term stability in policy frameworks is also emphasized, arguing that efficiency programs should be maintained for at least 10 years to give businesses confidence in making investments.

Energy audit programs could be strengthened, for instance by making it mandatory for businesses to report motor inventories and to act on the recommended energy efficiency measures. Additionally, EEOS frameworks could be improved by incorporating specific provisions for motor replacement.

In addition to these general recommendations, the report provides country-specific policy recommendations tailored to the regulatory and market conditions in Austria, Germany, Greece, Portugal, and the Netherlands. Each country section outlines the current policy landscape, identifies key barriers and presents refined recommendations based on stakeholder feedback from National Workshops and Co-Creation Workshops.

D5.2 EU-MORE Final Report – Brochure in 7 languages available

Here is our final report in 16-page appealing brochure format summarizing the starting point and key objectives of our project and to present to our kind stakeholders our final outcomes, results, conclusions and recommendations for future activities to support EU Member States under their obligations in EED.

For English please use the download button at the end.

For all other language versions, please use the following links here:

and for English here below:

Deliverable D6.2 – Replication of Policies

As part of Work Package 6, we analysed the possibilities of replicating the developed policies for replacing electric motors to other, related products categories where similar barriers to the accelerated uptake of more efficient units are identified. These product categories include, among others, pumps and fans, transmission systems (gear, belt-drive), and entire cooling systems and air compressors. We analysed existing programmes aiming to directly or indirectly stimulate the uptake of more efficient units in these product categories and calculated the potential impact of replacing older units.

Programmes already identified in the EU-MORE Review of Past and Existing Policies for the Acceleration of Electric Motor Renovation (D2.2) [1] are further analysed, with a focus on elements of motor driven systems (pumps, fans, air compressors, chillers). To this, the analysis added similar programmes that were not tackled by the EU-MORE motor policy review. We identified programmes for motor driven systems (such as compressors, pumps, or fans) in 14 countries. They cover the full range of policy instruments, from awareness raising activities and trainings, over audit programmes, to financial incentives and white certificate schemes.

D4.3 Policy impact analysis

The EU-MORE project, in its Work Package 4 (WP4), aims to develop and implement tools for the projection, monitoring, and evaluation of motor replacements. The central pillar of these efforts is the developed EU-MORE Motor Model (EU-M³), a comprehensive analytical tool designed to measure the impact of existing and emerging policies on the energy consumption and greenhouse gas emissions of electric motors.

The purpose of this report is to explain the development and functionality of the model, the process of policy selection and finally to provide examples of policy impact modelling.

Deliverable D2.4 – Analysis of end-of-life practice for electric motors

The EU-MORE Deliverable D2.4 report examines the critical interplay between motor replacement, energy efficiency gains, and the principles of circular economy. As the EU accelerates motor renovation to improve energy efficiency and achieve its climate goals, this report investigates the implications for material use, recycling practices, and resource circularity.

EU-MORE final event summary report

Boosting energy savings in industry and the service sector by accelerating replacement of old and inefficient electric motors.

The final event of the EU-MORE project took place in Brussels on March 11th. About 50 participants attended the event, where they had the opportunity to learn about the achievements of the EU-MORE project and provide valuable feedback on the policy recommendations and tools developed.

Beside speakers from our EU-MORE projects, we were proud to welcome also presentations from the other LIFE x3 Cluster projects: AUDIT2MEASURE and KNOWnNEBs, as well as DG Ener and CLASP.

The presentation PPT slide decks can be downloaded here: final event presentations

Please download the summary report here:

Date & Time

March 4, 2025 ; 15h00 - 16h00 CET

Speaker

Kurt Stockman, Ghent University, Department of Electromechanical Systems and Metal Engineering

recording on YouTube here: https://youtu.be/WBQ0K9pCvLU

Description

This webinar outlines the process of implementing a successful worldwide motor replacement programme at a large steel wire company. To meet its sustainability goals, the company decided to evaluate the potential benefits of upgrading to high-efficiency motors (IE4 or IE5) in its wire drawing machinery. The installed base consists of over 1,000 machines, which originally used frequency-controlled IE2 and IE3 induction motors.

Prof. Kurt Stockman of Ghent University will discuss the various phases of the project, starting with the collection of energy efficiency data from manufacturers. He will also cover the validation testing of this data based on motor performance assessments and an analysis of the compatibility of the selected high-efficiency motors with the original power electronic converters. The motor analysis includes induction motors, synchronous reluctance motors, and permanent magnet motors.

Following the technical evaluation of potential energy savings, the economic factors, including payback periods, were analysed. Additionally, the presentation will address the complexities of different energy costs across various regions worldwide and their impact on the payback period.

Finally, the speaker will discuss the actual rollout of the motor replacement initiative and share the initial field results of the energy measurements.

Following the presentation, you will have plenty of time to engage with the speaker during the Q&A session.

Maximizing energy efficiency in industry: Insights and policy recommendations from three EU-LIFE projects

Date & Time

February 21, 2025 ; 10h00 - 11h30 CET

Speakers

Recording on YouTube: https://youtu.be/aEHegIaE7MU

Description

EU-MORE, AUDIT2MEASURE, and KNOWNnNEBs—three LIFE co-funded projects aimed at promoting energy efficiency in industry—share their insights and policy recommendation for accelerating the implementation of energy efficiency measures.

AUDIT2MEASURE: Boost the impact of audits: How to implement Art. 11 of the EED into national legislation

Under the new Energy Efficiency Directive (EED), EU Member States are required to transpose the provisions of the new Article 11 of the revised EED (formerly Article 8) into national law by October 2025. The first version of AUDIT2MEASURE’s policy recommendation report provides insights and guidance on how national policymakers can improve the impact of their current national energy audit systems, fill current gaps, go beyond the minimum European requirements and how the European Commission could further support efforts to reduce energy consumption and greenhouse gas emissions in the industry.

download presentation here: https://eu-more.eu/wp-content/uploads/2025/03/01-AUDIT2MEASURE.pdf

KNOWnNEBs: Beyond Energy Savings: A comprehensive decision-making tool for Energy Efficiency in industry

This presentation introduces a comprehensive tool created under the KNOWnNEBs project for assessing energy efficiency measures. The tool captures energy savings and considers intangible benefits, such as improved air quality, increased productivity, and enhanced product quality. It also recognizes potential drawbacks, including operational disruptions, staff training complexities, and the risk of low construction quality. By utilizing advanced financial metrics like NPV, IRR, and ROI, along with a novel benefit indicator, it helps industry professionals, policymakers, and other stakeholders make informed decisions on energy efficiency investments. This ultimately leads to more effective industry practices and policy outcomes.

download presentation here: https://eu-more.eu/wp-content/uploads/2025/03/02-KNOWnNEBs.pdf

EU-MORE: Policy Review and recommendations for accelerating the replacement of old and inefficient motors

Electric motors used in industrial applications often remain in service beyond their expected lifespan, limiting the benefits of newer, more efficient motors. The EU-MORE project aims to capitalize on the advantages of accelerating the replacement rate of old, inefficient motors by developing new policies. To achieve this, a review of past and current policies affecting industrial electric motors in the 27 EU Member States was conducted. The presentation comprises the results of the EU-MORE Policy Review and the developed sets of Policy Recommendations taking into account feedback – among other - from discussions with stakeholders during national and co-creation workshops.

download presentation here: https://eu-more.eu/wp-content/uploads/2025/03/03-EU-MORE.pdf

recordings of our webinar now available here

Speaker

Robin Barkhausen, Fraunhofer ISI

Description

This webinar will discuss the EU-MORE Motor Model, designed to evaluate impacts from electric motor replacement policies. By allowing users to input various data, the model assesses the impacts on energy demand, material consumption and greenhouse gas emissions related to different policies. Its comprehensive stock model integrates these inputs to project outcomes such as energy and CO2 savings effectively. The results provide users, particularly policy makers, with a valuable tool for evaluating the implications of their policies.

Key takeaways

- The model clearly explains the impact of electric motor policy on energy, economic, and climate outcomes from the perspectives of policy makers and end users.

- Stakeholders can tailor the model to assess the policy impacts of replacement schemes, enhancing its practical relevance.

- The approach supports informed decision-making by policymakers on improvements to motor systems.

What are key success factors of financial incentive programmes for efficient electric motor systems?

Recording of our webinar now available here:

Speaker

Description

This webinar dives into the key insights from a recent Swiss study on the success factors of financial incentive programmes for electric motor systems.

Rita Werle, CEO and owner of Impact Energy, will discuss:

-

Evaluation of Swiss competitive tenders: A deep dive into competitive tenders as a tool for subsidising energy efficiency improvements in electric motor systems and other energy-consuming equipment.

- Building blocks of financial incentive programmes: Key factors for success in creating effective financial incentives for motor systems, with a focus on design and implementation.

- Exploring possible financial incentive modalities: Discussion on different approaches, including the balance between standard measures and tailored incentives, and their impact from a programme management and energy-saving perspective.

- Insights into Swiss energy efficiency obligations: An overview of ongoing efforts in Switzerland to implement an energy efficiency obligation scheme for utilities.

Key takeaways

- Key factors of a successful programme:

- Contact to programme participants

- Awareness within target group

- Easy participation

- Tangible subsidy

- Qualification of involved consultants

- Programme design depends on the objectives

- Switzerland goes ahead with energy efficiency obligations for electricity suppliers

Boosting efficiency: EU-MORE’s policy review on replacing inefficient motors in industry and services

Recordings of our webinar now available here:

Speakers

- Ronald Piers de Raveschoot, European Commission DG ENER.B3

- Ivan Sangiorgio, IEECP

- João Fong, ISR University of Coimbra

Description

Electric motors used in industrial applications often remain in service beyond their expected lifespan, limiting the benefits of newer, more efficient motors. The EU-MORE project aims to capitalize on the advantages of accelerating the replacement rate of old, inefficient motors by developing new policies. To achieve this, a review of past and current policies affecting industrial electric motors in the 27 EU Member States was conducted. The review includes 64 policy measures aimed at promoting the early replacement of motors to improve energy efficiency in industries. Each policy measure was characterized with details such as the national responsible authority, implementation timeline, available budget, and impacts on electricity savings and replaced industrial motors.

The review process relied on contributions from various country experts who provided a high-level perspective on the national policies under examination. The results show a strong prevalence of financial measures (subsidies and loans), followed by mandatory standards, fiscal measures, and voluntary agreements. The review also highlighted a significant lack of measures targeting trainings and information, deemed particularly relevant for industrial SMEs. Few national policies are incorporating systemic approaches to motor systems, such as including the supply and demand sides of motive power.

The review is complemented by an analysis of relevant motor policies implemented outside the European Union.

Key takeaways

- The EU-MORE project has conducted a review of EU policies supporting the early replacement of electric motors, highlighting the predominance of policies addressing only economic barriers.

- Only a few programs in the EU have tried to tackle information and behavioral barriers.

- The replacement of inefficient motors is generally integrated into cross-cutting programs that do not define specific eligibility criteria for motor replacement.

- The effectiveness of policy measures supporting motor replacement actions is difficult to assess due to the general lack of publicly available data about the policy impact.

- 2 Ronald Piers

- 3 Ivan Sangiorgio

D4.2 Stock-model to assess the policy impact of motor policies

The EU-MORE motor model (EU-M³) was developed with the main objective of analysing the impact of existing and new directives on the replacement of electric motors. The motivation behind the development of this tool is to enable stakeholders, especially policy makers, to understand the far-reaching implications of decisions in motor policy and to provide them with a platform for conducting their analyses

you can download the excel based tool here.

for an online version to try first, please see section "News" on this website.

D 4.1. MOTOR SYSTEM EFFICIENCY TRENDS

Growing awareness in governments and industry about the importance of energy-efficiency and its multiple benefits, together with the increasing number of countries implementing minimum energy performance standards (MEPS) for motors, has led to great improvements in the energy efficiency of motors. These now reach levels well above IE3, known as super- and ultra-premium efficiency motors (IE4 and IE5, respectively). Induction motors with IE4 efficiency are now widely available on the market.

Technologies such as permanent magnet motors and synchronous reluctance motors make it even possible to exceed the IE4 and IE5 efficiency limits (see Figure 1).

Three-phase squirrel cage induction motors (SCIM) are still the preferred choice for fixed speed applications because of their reliability. Other technologies capable of starting direct-on-line (DOL) have also appeared, such as line-start permanent magnet motors (LSPM) and DOL synchronous reluctance motors (SynRM), but they still show some operational drawbacks limiting their widespread use.

Conversely, in applications where speed variation is necessary, permanent magnet synchronous motors (PMSM) and Synchronous Reluctance Motors (SynRM) are considered viable alternatives to induction motors, rivalling in reliability and excelling in efficiency. Operating at synchronous speed, these motors eliminate rotor losses, which can lead to very high efficiency levels, even exceeding IE5.

D2.1 European Electric Motor Market Assessment

This report presents an assessment of the EU-27 electric motor market. It provides information, collected from different sources, on the number of motor sales categorised by technology, power range and efficiency class. The report also includes tables and figures that depict the production, sales and consumption of electric motors in the EU-27, as well as estimates of the motors’ installed base and its electricity consumption. These last two figures remain with a large degree of uncertainty, as recent and credible sources for the underlying assumptions are lacking. In particular, discrepancies between the results of various calculation methods for the electricity consumption remain unsolved. This underscores the importance of having accurate and recent data on the characteristics of the motors’ installed base.

The data presented in this report will serve as a baseline for estimating the savings potentials associated with the policy recommendations elaborated by EU-MORE.

EU-MORE at Coiltech Germany in Mar 2024

Trends in motor technologies, and why old electric motors should be replaced faster – presented by the EU-MORE project at Coiltech trade show & World Magnetic Conference in Augsburg end of March 2024.

Early 2024, EU-MORE has reached its next milestone with the publication of a comparative review on motor technologies, including an analysis of motor system optimization benefits. MEPSs for motors have led to major improvements in the energy efficiency of motors, which now reach levels known as Super- and Ultra-Premium Efficiency Motors (IE4 and IE5). This review discusses the latest trends in IM, SynRM and PM, highlights some aspects of direct-on-line starting motors. The review also digs into the energy saving potential of VSDs, further digitalization and other types of system optimization.

EU-MORE D2.2 – Review of past and existing policies for the acceleration of electric motor renovation [LIGHT VERSION]

The Light Version of the EU-MORE Policy Review includes the report's results, the country review template adopted and a summary table of the analysed policy measures.

EU-MORE D2.2 – Review of past and existing policies for the acceleration of electric motor renovation [FULL VERSION]

Electric motors for industrial applications have the tendency to stay in service longer than their expected lifetime and be replaced only at their end-of-life, limiting the benefits of the higher efficiency of new motors. The EU-MORE project aims to capture the benefits of accelerating the replacement rate of old, inefficient motors through the development of new policies. To accomplish this, a review of past and existing policies targeting industrial electric motors has been conducted for 27 European Member States. The review encompasses 64 policy measures targeting directly and indirectly the early replacement of motors as a measure to improve energy efficiency in industries. Each policy measure is presented with a short description, responsible authority, status, issue date, start date, end date, duration, and reference to the official publication. Additionally, a preliminary estimation of the impact of the analysed measures has been conducted.

The review methodology is based on the contribution of several country experts able to provide a high-level perspective on the national policies under exam.

The results show a strong predominance of financial measures, mostly subsidies and loans (or combinations of them), followed by mandatory standards, fiscal measures and voluntary agreements. The review highlighted a very low implementation of measures targeting trainings and information, particularly relevant for industrial SMEs. On a national level, Germany resulted the country with the highest number of measures involving electric motors, followed by Austria. Very few national policies include systemic approaches to motor systems (i.e. including the overall supply of motive power as well as the demand side for motive power), which generate usually the highest energy savings, as evidenced from case studies.

The report is complemented by an in-depth presentation of measures directly targeting industrial electric motors across the Member States.

The Full Version of this deliverable includes the review reports of the 27 Member States.

Speeding up the adoption of state-of-the-art electric motors

The European project EU-MORE (an acronym for EUropean MOtor REnovation initiative) aims at seizing the benefits deriving from the acceleration of the replacement rate of old inefficient motors through the development of new policies.

EMSA policy brief: Key findings on digitalisation technologies for motor systems

This Policy Brief gives an overview of the content of the EMSA report on

Classification of digitalisation technologies for electric motor driven systems.

The report identifies 13 digital technologies with the potential to influence energy

consumption in electric motor driven systems and contains definitions, descriptions and examples in this area.

Perspectives on Electric Motor Market Transformation for a Net Zero Carbon Economy

New paper by

Anibal T. de Almeida , Fernando J. T. E. Ferreira and João Fong

Department of Electrical and Computer Engineering, ISR-University of Coimbra, Portugal

As electric motors systems represent such a large share of the overall electricity consumption (over 50%), large savings potential could be made available by the use of energy-efficient motor systems both in new installations and by accelerating the replacement of old inefficient motors. Since electric motors are very reliable, their lifetime is long (according to recent studies it may exceed 20 years) which translates into a very inefficient existing stock despite worldwide policy efforts. This paper analyzes the current efficiency of the installed stock and the causes for its low efficiency, possible policy options to increase its the efficiency, the role of new technologies and improvements possible by targeting the entire motor system at the time of motor replacement. The paper presents an innovative analysis of the estimated impact of increasing the uptake of high-efficiency motors and motor systems; effective policies could translate into 100 TWh/year in the European Union if additional measures, such as addressing oversizing, proper controls (VSDs) and digitisation, are also implemented

ENERGY-EFFICIENT ELECTRIC MOTORS AND MOTOR SYSTEM

Improving energy efficiency is the fastest, cheapest and cleanest way to get reliable power to more people. Well over half of the world's electricity is consumed

by just four products: electric motor systems, lighting, room air conditioners, and residential refrigerators.

ENERGY EFFICIENT INDUSTRIAL MOTORS

Electric motors are of utmost importance in industrial as well as agriculture sector. These motors found their application as constant speed drives with very low rating as well as variable speed drives with very high rating. This paper describes the various factors affecting the efficiency of motor and method to increase it on the basis of comparison with various standards. An incremental difference in the efficiency is also discussed.